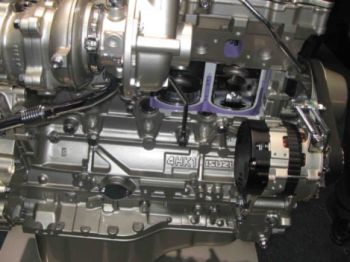

E320C(铝)液压油散热器

来源:E320C(铝)液压油散热器 发布时间:2024-06-21 17:42:39 作者:admin 阅读量:637

E320C新(铝)液压油散热器

水箱散热器 液压油散热器 中冷器厂家

水箱散热器 液压油散热器 中冷器厂家

专业开发工程机械高品质加厚加密度水箱散热器 中冷器 液压油散热器,应用于沃尔沃、卡特、小松、日立、大宇、现代、住友、神钢、柳工、三一、龙工、中联重科等进口和国产重型机械。耐用度更高,散热性更好。欢迎来电咨询及选购。

电话: 13503002418

网址:http:// www.iisuzu.com